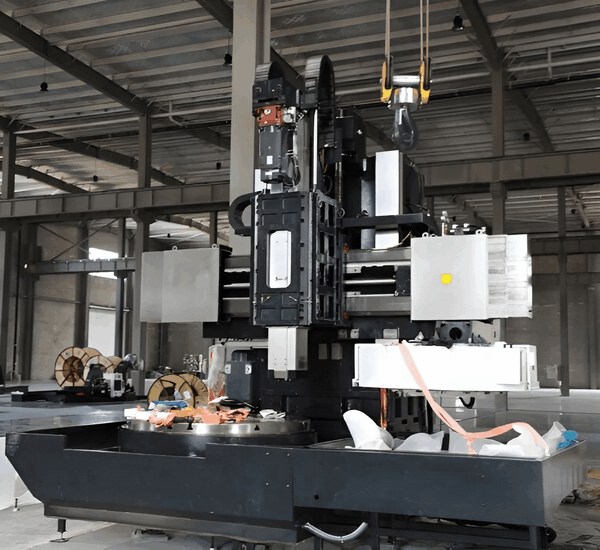

Se stále rostoucí poptávkou po přesném obrábění, CNC vertikální soustruhy se staly nepostradatelnou součástí zpracovatelského průmyslu. Pokud hledáte CNC vertikální soustruh, jste na správném místě. Tento článek poskytuje komplexní průvodce CNC vertikálními soustruhy na prodej, pokrývající klíčové vlastnosti, výhod, a úvahy před nákupem.

Co je CNC vertikální soustruh?

CNC (Počítačové numerické ovládání) vertikální soustruh je typ stroje, který provádí různé operace, jako je soustružení, frézování, a vrtání do kovových obrobků. Funguje pod kontrolou počítačového programu, zajištění přesnosti a opakovatelnosti ve výrobním procesu.

Klíčové vlastnosti CNC vertikálního soustruhu

1. Vysoká přesnost: CNC vertikální soustruhy nabízejí vysoce přesné možnosti obrábění, zajištění přesných a konzistentních výsledků.

2. Všestrannost: Tyto stroje mohou provádět více operací, včetně soustružení, frézování, a vrtání, na různé materiály.

3. Snadné programování: Moderní CNC vertikální soustruhy přicházejí s uživatelsky příjemným rozhraním, usnadňuje operátorům programování a řízení stroje.

4. Vysoká produktivita: Díky jejich vysoké rychlosti a přesnosti, CNC vertikální soustruhy mohou zvýšit produktivitu výroby.

Výhody CNC vertikálního soustruhu

1. Zlepšená účinnost: CNC vertikální soustruhy automatizují opakující se úkoly, snížení potřeby ruční práce a zlepšení efektivity.

2. Snížení nákladů: Automatizace snižuje celkové náklady na výrobu, protože je zapotřebí méně zdrojů pro ruční práci a plýtvání materiálem je minimalizováno.

3. Vysoce kvalitní výstup: S vysoce přesnými schopnostmi, CNC vertikální soustruhy zajišťují konzistentní vysoce kvalitní výstup.

Úvahy před koupí CNC vertikálního soustruhu

1. Specifikace stroje: Zvažte specifikace stroje, jako je jeho síla, rozsah rychlosti, a maximální velikost obrobku, aby bylo zajištěno, že splňuje vaše výrobní potřeby.

2. Pověst značky: Prozkoumejte různé výrobce a jejich pověst v oboru, abyste se ujistili, že kupujete spolehlivý stroj.

3. Cena vs. hodnota: Zvažte cenu stroje v porovnání s jeho funkcemi a výhodami, abyste měli jistotu, že za své peníze dostanete tu nejlepší hodnotu.

4. Poprodejní servis: Ujistěte se, že výrobce poskytuje dobrý poprodejní servis, včetně technické podpory a dostupnosti náhradních dílů.

Pokud hledáte CNC vertikální soustruh na prodej, je důležité zvážit všechny tyto faktory, abyste měli jistotu, že si koupíte stroj, který vyhovuje vašim potřebám a rozpočtu. Se správným strojem, můžete výrazně zlepšit efektivitu a produktivitu výroby.