Rozdíl mezi vřetenem řady HSK a vřetenem modelu BT ve stabilitě

Ve zpracovatelském průmyslu, vřetena jsou klíčové komponenty, které hrají zásadní roli ve stabilitě a výkonu strojů. Běžně se používají dva hlavní typy vřeten, jmenovitě série HSK a vřetena modelu BT. Zatímco oba typy nabízejí své vlastní jedinečné výhody a nevýhody, zvláště pozoruhodné jsou jejich charakteristiky stability.

Vřeteno řady HSK

HSK znamená typ vřetena, který je známý svými vysokorychlostními schopnostmi a přesným obráběním. Konstrukce vřetena řady HSK zahrnuje prvky, které zajišťují stabilitu při vysokorychlostních operacích. Rozhraní vřetena je speciálně navrženo tak, aby poskytovalo maximální přesnost a stabilitu pro širokou škálu výrobních aplikací. Dodatečně, vřeteno řady HSK nabízí snadnou integraci do obráběcích strojů díky svému standardizovanému rozhraní.

Model BT vřeteno

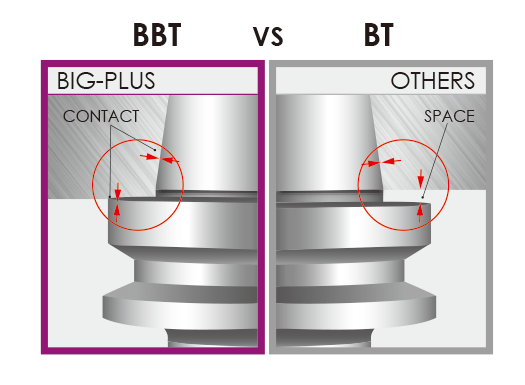

BT znamená \ obráběcích strojů a vyznačuje se robustní konstrukcí a vysokými točivými momenty. Vřeteno modelu BT je navrženo tak, aby poskytovalo stabilitu během náročných obráběcích operací. Jeho konstrukce zahrnuje vlastnosti, které nabízejí vysokou axiální a radiální tuhost, které přispívají k jeho výjimečným charakteristikám stability. Dodatečně, vřeteno modelu BT je kompatibilní se širokou škálou nástrojů, díky tomu je univerzální pro různé výrobní aplikace.

Srovnání ve stabilitě

Srovnání ve stabilitě

Při porovnání stability vřeten řady HSK a modelu BT, je důležité zvážit jejich zamýšlené aplikace. Vřetena řady HSK jsou známá svými vysokorychlostními schopnostmi a přesným obráběním, zatímco modelová vřetena BT vynikají v náročných obráběcích operacích. Vřeteno řady HSK nabízí vynikající stabilitu při vysokých rychlostech díky své optimalizované konstrukci a rozhraní. Však, vřeteno modelu BT poskytuje výjimečnou stabilitu při velkém zatížení díky své robustní konstrukci a vysokým točivým momentům.

Navíc, oba typy vřeten nabízejí různé úrovně tuhosti, což také přispívá k jejich stabilitním charakteristikám. Tuhost vřetena je rozhodující pro zajištění přesných a stabilních obráběcích operací. Vřeteno řady HSK nabízí vysokou axiální tuhost, zatímco vřeteno modelu BT nabízí vysokou radiální tuhost. Tento rozdíl v tuhosti zajišťuje, že oba typy vřeten nabízejí stabilitu v různých aplikacích na základě orientace stroje a typu použitého nástroje..

Celkově, stabilita vřeten řady HSK a modelů BT závisí na jejich zamýšlených aplikacích a vlastnostech strojů, na kterých se používají. Oba typy nabízejí výjimečnou stabilitu ve svých příslušných oborech, což z nich dělá spolehlivé komponenty pro různé výrobní operace.