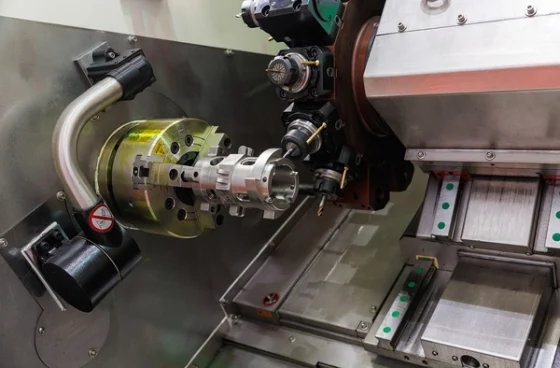

Med den hurtige udvikling af fremstillingsindustrien, Det præcisionsbearbejdningsfelt for udstyrskrav øges også. Dobbelt spindel CNC inverteret drejebænk som en ny generation af sammensat bearbejdningsudstyr, med sin høje effektivitet, præcision, stabilitet, er blevet en vigtig og uundværlig rolle i den moderne fremstillingsindustri. I dette papir, Vi vil introducere egenskaberne og fordele ved dobbelt spindel CNC omvendt drejebænk og dens anvendelse inden for præcisionsbearbejdning.

Først, Dobbelt spindel CNC Inverted Lathe er et meget automatiseret præcisionsbearbejdningsudstyr, brugen af dobbelt spindeldesign, Forbedring af behandlingseffektiviteten meget. Dens seng er omvendt, Hvilket gør det lettere at fodre og tage materialer ud under bearbejdning. Udstyret med avanceret CNC -system, Det er i stand til at realisere højpræcision og højstabilitetsbehandling.

Anden, Egenskaberne ved dobbelt spindel CNC inverteret drejebænk

1. Dobbelt spindeldesign: Det dobbelte spindeldesign gør, at maskinværktøjet kan betjenes i to forskellige processer på samme tid under bearbejdningsprocessen, Hvilket forbedrer bearbejdningseffektiviteten i høj grad.

2. CNC -system: Brugen af avanceret numerisk kontrolsystem kan realisere behandling med høj præcision og højstabilitet. Samtidig, CNC -systemet kan også realisere automatisk drift og reducere arbejdsomkostningerne.

3. Inverteret struktur: Inverteret struktur gør det lettere at fodre og tage materialerne ud under bearbejdningsprocessen og reducere driftsproblemet.

4. Høj styrke seng: Seng med høj styrke sikrer maskinens stabilitet under højhastighedsdrift og forbedrer bearbejdningsnøjagtigheden.

5. Bred anvendelighed: Dobbelt spindel CNC inverteret drejebænk er velegnet til behandling af forskellige præcisionsdele, såsom forme, hardware, bildele og så videre.

Tredje, Fordelene ved dobbelt spindel CNC inverteret drejebænk

1. høj effektivitet: Dobbelt spindeldesign gør, at værktøjsmaskinen kan realisere multi-task parallel behandling, Forbedring af behandlingseffektiviteten meget.

2. Høj præcision: Avanceret CNC-system og høj styrke seng for at sikre høj præcisionsbearbejdning.

3. Høj stabilitet: Inverteret struktur og optimeret mekanisk strukturdesign får maskinen til at opretholde høj stabilitet under lang tid drift.

4. Let at betjene: Den automatiske drift af CNC -systemet reducerer vanskeligheden ved manuel drift og forbedrer produktionseffektiviteten.

5. Bred vifte af applikationer: Velegnet til en række forskellige præcisionsdele -behandling, til udvikling af fremstillingsindustrien til at yde stærk støtte.

Fjerde, Dobbelt spindel CNC inverteret drejebænk har en bred vifte af applikationer inden for præcisionsbearbejdning. For eksempel: i præcisionsmaskinerfremstilling, Produkter af disktype på begge sider af for- og bagside skal være at dreje bore- og fræsningsforbindelsesbehandling. Dobbelt spindel CNC inverteret drejebænk kan realisere høj præcision, Høj effektivitetsbehandling, Forbedre behandlingskvalitet og produktivitet. Derudover, i bilproduktion, Hardwarefremstilling og andre felter, Dobbelt spindel CNC inverteret drejebænk spiller også en vigtig rolle.

Konklusion:Afslutningsvis, Som repræsentant for en ny generation af præcisionsbearbejdningsudstyr, dobbelt spindel CNC inverteret drejebænk, med sin høje effektivitet, nøjagtighed og stabilitet, er blevet en uundværlig og vigtig rolle i moderne fremstillingsindustri. I den fremtidige udvikling, Dobbelt spindel CNC inverteret drejebænk vil fortsat spille sin vigtige rolle inden for præcisionsbearbejdning, at yde stærk støtte til den hurtige udvikling af fremstillingsindustrien.

WhatsApp

Scan QR-koden for at starte en WhatsApp-chat med os.