VMC850 and VMC1060 technical parameters:

| Progetto Name | Unit | VMC850 Parameter | VMC1060 Parameter | |

| Table | Worktable size | mm | 1000×500 | 1200×600 |

| Max. worktable load | KG | 800 | 1000 | |

| T slot (number-width) | mm | 18×5 | 18×5 | |

| Travel Range | Corsa dell'asse X | mm | 800 | 1000 |

| Y axis travel | mm | 500 | 600 | |

| Corsa dell'asse Z | mm | 600 | 600 | |

| Distance between spindle nose and table surface | mm | 120-720 | 120-720 | |

| Spindle center to column guide-way face | mm | 530 | 650 | |

| Spindle Parameters | Spindle model | BBT | BBT40 | BBT50 |

| Spindle diameter | mm | Φ150 | Φ190 | |

| Velocità del mandrino | rpm/min | 12000 or 15000 or 12000 | 10000 or 12000 or 6000 | |

| Spindle drive method | Motor | Belt or Direct or Gear | Belt or Direct or Gear | |

| Potenza del motore del mandrino | KW | 11 | 15 | |

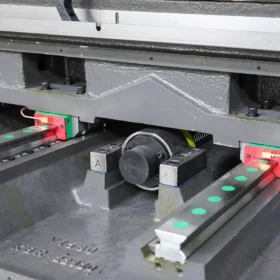

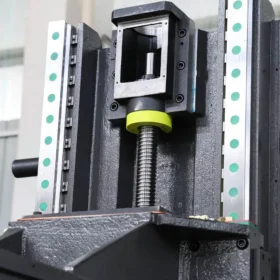

| Drive Method | Ball screw accuracy | C | C3 | C3 |

| linear guide model | mm | XYZ:45 | XY:45 Z:55 | |

| Traverse Speed | X rapid traverse speed | m/min | 36 | 24 |

| Y rapid traverse speed | m/min | 36 | 24 | |

| Z rapid traverse speed | m/min | 24 | 18 | |

| Cutting Feed Speed | Z axis cutting feed speed | m/min | 12 | 10 |

| CNC Tool Magazine Types | Tool magazine type | Servo type | Disc tool magazine | Disc tool magazine |

| Tool number | T | 24 | 24 | |

| Tool holder model | BBT | BBT40 | BBT50 | |

| Tool change time | S | 2 | 2 | |

| Positioning Unccuracy | X axis positioning accuracy | μm | 4μm(full travel) | 6μm(full travel) |

| Y axis positioning accuracy | μm | 3μm(full travel) | 4μm(full travel) | |

| Z axis positioning accuracy | μm | 4μm(full travel) | 4μm(full travel) | |

| Repeat Positioning Unccuracy | X axis repeat positioning accuracy | μm | 2μm(full travel) | 3μm(full travel) |

| Y axis repeat positioning accuracy | μm | 1.5μm(full travel) | 2μm(full travel) | |

| Z axis repeat positioning accuracy | μm | 2μm(full travel) | 2μm(full travel) | |

| Complessivamente Dimension | (L*W*H) | mm | 2600×2300×2800 | 3300×2600×2950 |

| Weight | Peso netto | KG | 6700 | 8500 |

VMC1370 and VMC1580 technical parameters:

| Progetto Name | Unit | VMC1370 Parameter | VMC1580 Parameter | |

| Table | Worktable size | mm | 1500×700 | 1700×800 |

| Max. worktable load | KG | 1300 | 1500 | |

| T slot (number-width) | mm | 22×5 | 22×5 | |

| Travel Range | Corsa dell'asse X | mm | 1300 | 1500 |

| Y axis travel | mm | 700 | 800 | |

| Corsa dell'asse Z | mm | 700 | 700 | |

| Distance between spindle nose and table surface | mm | 150-850 | 170-870 | |

| Spindle center to column guide-way face | mm | 750 | 850 | |

| Spindle Parameters | Spindle model | BBT | BBT50 | BBT50 |

| Spindle diameter | mm | Φ190 | Φ190 | |

| Velocità del mandrino | rpm/min | 10000 or 12000 or 6000 | 10000 or 12000 or 6000 | |

| Spindle drive method | Motor | Belt or Direct or Gear | Belt or Direct or Gear | |

| Potenza del motore del mandrino | KW | 15 or 18.5 | 18.5 or 22 | |

| Drive Method | Ball screw accuracy | C | C3 | C3 |

| linear guide model | mm | XY:45 Z:55 | X:55 Y:45 Z:55 | |

| Traverse Speed | X rapid traverse speed | m/min | 16 | 12 |

| Y rapid traverse speed | m/min | 16 | 12 | |

| Z rapid traverse speed | m/min | 12 | 12 | |

| Cutting Feed Speed | Z axis cutting feed speed | m/min | 10 | 10 |

| CNC Tool Magazine Types | Tool magazine type | Servo type | Disc tool magazine | Disc tool magazine |

| Tool number | T | 24 | 24 | |

| Tool holder model | BBT | BBT50 | BBT50 | |

| Tool change time | S | 2 | 2 | |

| Positioning Unccuracy | X axis positioning accuracy | μm | 8μm(full travel) | 9μm(full travel) |

| Y axis positioning accuracy | μm | 4μm(full travel) | 4μm(full travel) | |

| Z axis positioning accuracy | μm | 4μm(full travel) | 4μm(full travel) | |

| Repeat Positioning Unccuracy | X axis repeat positioning accuracy | μm | 4μm(full travel) | 4μm(full travel) |

| Y axis repeat positioning accuracy | μm | 2μm(full travel) | 2μm(full travel) | |

| Z axis repeat positioning accuracy | μm | 2μm(full travel) | 2μm(full travel) | |

| Complessivamente Dimension | (L*W*H) | mm | 3800×2900×3000 | 4250×3250×3150 |

| Weight | Peso netto | KG | 10500 | 13000 |