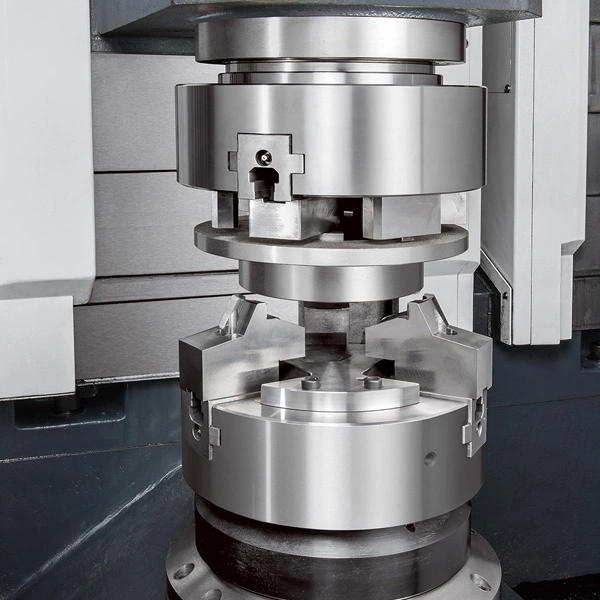

Урвуу CNC босоо каталь бүтэцийг ашиглан тоормосны диск боловсруулах. Автомашины үйлдвэрлэлийн хөгжлийг ашиглан тоормослох, тоормос диск, Автомашины аюулгүй ажиллагааг аюулгүй ажиллагааны үндсэн бүрэлдэхүүн хэсгийн нэг, Түүний боловсруулах технологи нь бас дэвшиж байна. Тоормосны дискийг өндөр нарийвчлалтай боловсруулах эрэлтийг хангахын тулд, Урвуу cnc босоо зэргийг тоормослох, тоормосны дискний үйлдвэрлэлд өргөн хэрэглэгддэг.

Би. Урвуу CNC босоо кате бол дараахь функц бүхий өндөр үр ашиг, өндөр үр ашиг, өндөр түвшний машин механик төхөөрөмж юм:

1. Үр дүнтэй бүтцийн загвар: Урвуу CNC босоо катти нь урвуу бөөсний дизайныг өргөжүүлдэг, урагшлах явцад тайрах хүчийг хөдөлгөж байгаа юм, Машины багаж хэрэгслийн ачааллыг бууруулж, машин механизмын тогтвортой байдал, боловсруулах, боловсруулах чадварыг сайжруулахад таатай байна.

2. Нарийвчилсан хяналтын систем: Дэвшилтэт тоон хяналтын системийг ашиглах, өндөр нарийвчлалтай ойлгож чадна, Өндөр хурдтай боловсруулах, нарийн төвөгтэй машин боловсруулах, боловсруулах шаардлагыг биелүүлэх боломжтой.

3. АВТОМАШИНЫ АВТОМАШИНГ: Урвуу CNC босоо кате нь автомат ачаалах, буулгах төхөөрөмжөөр тоноглогдсон, Автомат хэмжих төхөөрөмж болон бусад туслах тоног төхөөрөмж, автомат үйлдвэрлэл, үйлдвэрлэлийн үр ашгийг дээшлүүлэх боломжтой.

Хоёрдахь нь, Урвуу CNC босоо тоорментийг тоормосны дискний боловсруулалт хийхэд тусгайлан боловсруулсан болно, тоормосны дискийг өндөр нарийвчлалтайгаар боловсруулах эрэлт хэрэгцээг хангаж чадах. МЭДЭЭЛЛИЙН МЭДЭЭЛЛИЙН НЭГДСЭН НЭГДСЭН ШУУД ҮЗЭХ:

1. Өрөмдлөгийн болон тоормосны тээрэмдэх тээрэмдэх (стандарт тохируулга): нарийвчлал, өрөмдлөгийг ухамсарлах, Дээд ба доод хэсгүүдийн автомат солилцоо, Бүтээгдэхүүний хувьд олон төрлийн машин боловсруулах үйл явцыг ухамсарлах.

2. Тоормосны дискийг нарийвчлалтай нунтаглах (Нэмэлт тохиргоо): тоормосны дээд ба доод хэсгийн нунтаглах, доод хэсгийн нунтаглах процессыг ашиглан тоормослох чадварыг хангах чадвартай байх чадвартай.

3. Автоматжуулсан үйлдвэрлэлийн шугамыг бий болгох (Нэмэлт тохиргоо): Автомат ачаалах, ачих төхөөрөмж, ачих төхөөрөмж, автомат хэмжих төхөөрөмж, автомат хэмжих төхөөрөмж, автомат хэмжих төхөөрөмжийг ашиглах замаар автоматжуулсан үйлдвэрлэлийг бий болгох боломжтой.

Гурав дахь, нэгтгэн дүгнэхэд, Автомашины үйлдвэрлэлийн тасралтгүй хөгжил, Тоормосны дискийг тусгай урвуу cnc босоо CNC босоо катти нь автомашины үйлдвэрлэлийн салбарт улам бүр чухал үүрэг гүйцэтгэдэг. Түүний өндөр нарийвчлалтай, АЖИЛЛАГАА АЖИЛЛАГААНЫ АЖИЛЛАГААНЫ АЖИЛЛАГААНЫ АВТОМАШИНГИЙН АВТОМАШИНГИЙН АВТОМАШИНГИЙН ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨ, ТОНОГ ТӨХӨӨРӨМЖ, ТОНОГ ТӨХӨӨРӨМЖ, ТОНОГ ТӨХӨӨРӨМЖИЙН ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ АЖИЛЛАГАА, Машиныг аюулгүй жолоодоход хүчтэй баталгаа өгөх.

Whatsapp

Whatsapp-ийг эхлүүлэхийн тулд QR кодыг сканнердах.