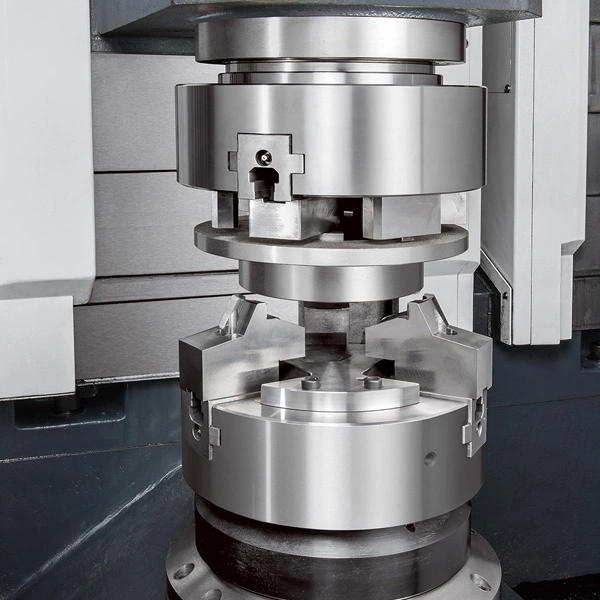

Brake disc machining is an integral part of the automotive industry, ensuring the safety and performance of vehicles. In recent years, the use of inverted CNC vertical lathes has become increasingly popular in this process due to their precision, ufanisi, na uboreshaji.

An inverted CNC vertical lathe is a sophisticated machine tool that is specifically designed for machining brake discs. It operates by rotating the brake disc vertically and using cutting tools to remove excess material and achieve the desired shape and surface quality. This machine combines advanced technology with precision engineering to deliver exceptional results.

The benefits of using an inverted CNC vertical lathe for brake disc machining are numerous. Kwanza, it ensures precision machining, resulting in high-quality brake discs that meet the specific requirements of manufacturers and vehicle owners. Pili, it improves efficiency by automating the machining process, reducing the dependence on manual labor and enabling faster turnaround times. Kwa kuongeza, it allows for better control over the machining process, resulting in improved product consistency and reduced defects.

Kwa kuongeza, an inverted CNC vertical lathe provides flexibility in terms of the materials that can be processed. It can handle various materials, including different types of metals and alloys, enabling manufacturers to accommodate different brake disc applications. This versatility further enhances the machine’s ability to adapt to changing industry demands and requirements.

In addition to its use in brake disc machining, an inverted CNC vertical lathe can also be used for other applications within the automotive industry. Its precision machining capabilities enable it to handle various tasks, such as machining rotors, hubs, and other automotive components. This versatility makes it a valuable tool for any automotive manufacturing facility.

Kwa jumla, the use of an inverted CNC vertical lathe for brake disc machining has revolutionized the automotive industry. Its precision, ufanisi, and versatility make it a crucial tool for ensuring the safety and performance of vehicles. As the industry continues to evolve, the use of this machine will become increasingly widespread, enabling manufacturers to meet the demands of a growing market.