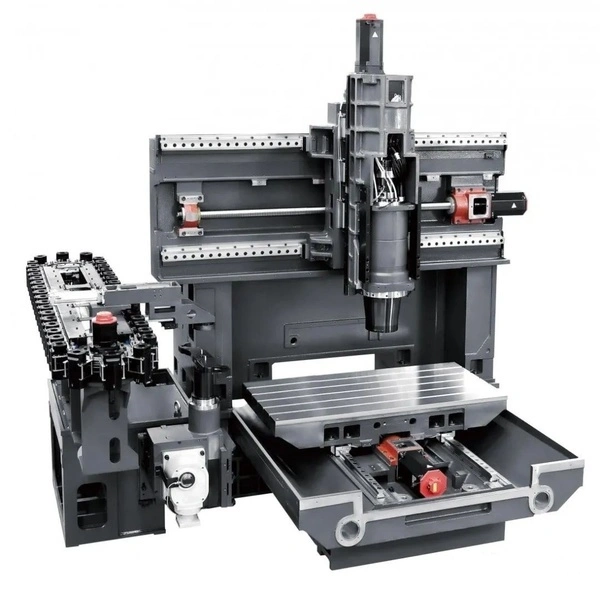

நவீன உற்பத்தித் துறையில், CNC மில்லிங் இயந்திரங்கள் பல்வேறு தொழில்களுக்கு இன்றியமையாத கருவியாக மாறியுள்ளன. When it comes to purchasing a CNC milling machine, the price becomes a crucial factor, and selecting the right machine at the right price is essential. This article delves into the key selection factors that influence the pricing of CNC milling machines.

Market Overview and Trends

Firstly, understanding the current market scenario and trends is vital. The cost of CNC milling machines varies depending on the market supply, new technology advancements, and overall industry demand. It’s important to research market prices, compare different models, and identify any recent changes in pricing.

Machine Specifications and Features

The price of a CNC milling machine largely depends on its specifications and features. Key factors such as the machine’s power, துல்லியம், speed, size, and the type of materials it can handle are crucial in determining its price. Higher-end machines with advanced features and specifications will typically have a higher price tag.

Brand and Manufacturer

The reputation and credibility of the brand and manufacturer also play a role in determining the price of a CNC milling machine. Established brands with a history of quality products and reliable after-sales service tend to charge higher prices. However, it’s important to strike a balance between brand reputation and cost, ensuring that you get value for your money.

Availability of After-Sales Support and Spare Parts

The availability of after-sales support and spare parts is another crucial factor to consider when selecting a CNC milling machine. Machines from reputable manufacturers often come with comprehensive after-sales support packages and a readily available supply of spare parts, which can add to the overall cost. However, this investment is worth it in ensuring the longevity and efficient performance of your machine.

Conclusion:In a word, there are several factors to consider when choosing a suitable CNC milling machine at the right price. Understanding market trends, evaluating machine specifications and functions, considering manufacturers, and considering after-sales support and the availability of spare parts are all key steps in this process. Balancing these factors will help you make informed decisions and ensure that you get a high-quality CNC milling machine that meets your needs.