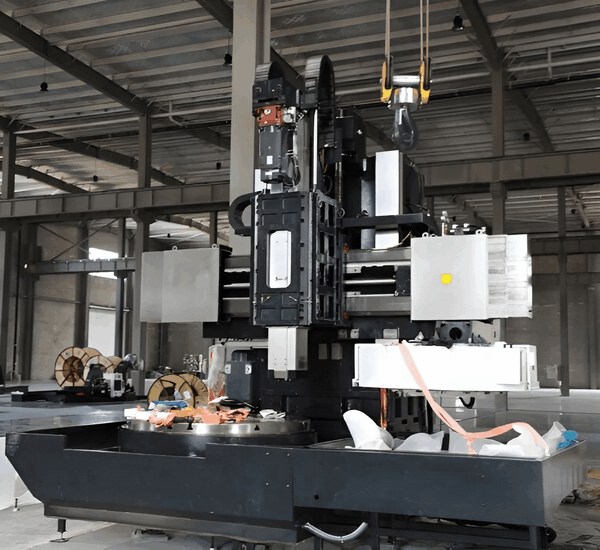

With the ever-growing demand for precision machining, CNC vertical turning lathes have become an indispensable part of the manufacturing industry. If you’re in the market for a CNC vertical turning lathe, you’ve come to the right place. This article provides a comprehensive guide on CNC vertical turning lathes for sale, covering key features, benefits, and considerations before purchase.

What is a CNC Vertical Turning Lathe?

A CNC (Bilgisayar Sayısal Kontrolü) vertical turning lathe is a type of machine that performs various operations such as turning, frezeleme, and drilling on metal workpieces. It operates under the control of a computer program, ensuring precision and repeatability in the manufacturing process.

Key Features of a CNC Vertical Turning Lathe

1. High precision: CNC vertical turning lathes offer high-precision machining capabilities, ensuring accurate and consistent results.

2. Versatility: These machines can perform multiple operations, including turning, frezeleme, and drilling, on various materials.

3. Easy programming: Modern CNC vertical turning lathes come with user-friendly interfaces, making it easy for operators to program and manage the machine.

4. High productivity: With their high speed and precision capabilities, CNC vertical turning lathes can increase productivity in manufacturing.

Benefits of a CNC Vertical Turning Lathe

1. Improved efficiency: CNC vertical turning lathes automate repetitive tasks, reducing the need for manual labor and improving efficiency.

2. Cost reduction: Automation reduces the overall cost of manufacturing, as fewer resources are required for manual labor and material wastage is minimized.

3. High-quality output: With high-precision capabilities, CNC vertical turning lathes ensure consistent high-quality output.

Considerations Before Purchasing a CNC Vertical Turning Lathe

1. Machine specifications: Consider the machine’s specifications, such as its power, speed range, and maximum workpiece size, to ensure it meets your manufacturing needs.

2. Brand reputation: Research different manufacturers and their reputation in the industry to ensure you’re buying a reliable machine.

3. Cost vs. value: Consider the cost of the machine in comparison to its features and benefits to ensure you’re getting the best value for your money.

4. After-sales service: Ensure the manufacturer provides good after-sales service, including technical support and spare parts availability.

If you’re looking for a CNC vertical turning lathe for sale, it’s important to consider all these factors to ensure you purchase a machine that meets your needs and budget. With the right machine, you can significantly improve your manufacturing efficiency and productivity.