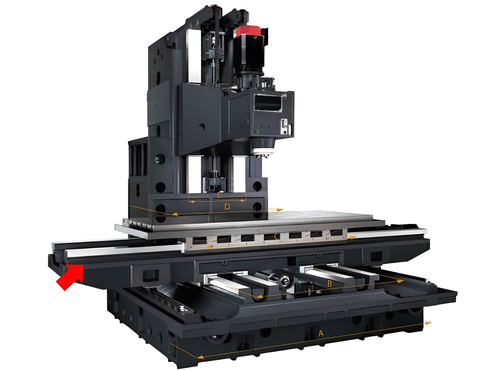

Looking for a reliable and efficient machine for your manufacturing business? A vertical CNC milling machine may be just what you need. This article outlines the key features and benefits of purchasing a vertical CNC milling machine for sale.

Uses of a Vertical CNC Milling Machine. A vertical CNC milling machine is widely used in various industries such as automotive, aerospace, and manufacturing. It is commonly used for cutting, drilling, routing, and milling different materials to create precise parts and components. The machine is also suitable for complex prototype manufacturing and mold making.

Benefits of Purchasing a Vertical CNC Milling Machine

1. Precision: CNC milling machines provide high precision and accuracy, ensuring that your parts meet the required specifications and tolerances.

2. Automation: The machine operates with minimal human intervention, reducing the need for skilled labor and saving time.

3. Versatility: Vertical CNC milling machines can work on various materials, including metal, plastic, wood, and more. They can also be easily programmed to perform different operations.

4. High Production Rates: The machine’s high speed and precision help increase production rates, leading to improved efficiency and profitability.

5. Durable: CNC milling machines are designed for heavy-duty operations and are built to last. They can handle long working hours without breaking down.

When purchasing a vertical CNC milling machine for sale, it is essential to consider factors such as the machine’s specifications, brand reputation, after-sales service, and cost. Ensure that you research thoroughly to find a machine that meets your specific needs and budget.

In conclusion, a vertical CNC milling machine is an excellent addition to any manufacturing business. Its precision, automation, versatility, high production rates, and durability make it a valuable asset for any workshop or factory. So why wait? Start exploring the different models available in the market today!