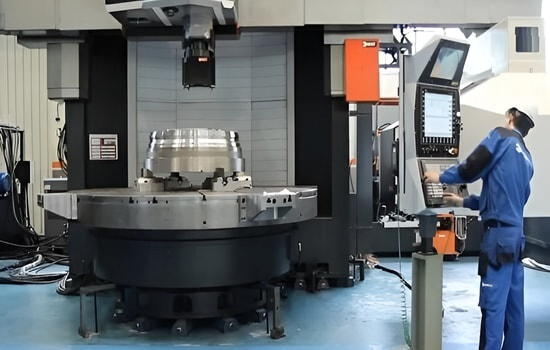

Trong ngành sản xuất, CNC (Điều khiển số máy tính) machines play a pivotal role in ensuring precision and efficiency in production processes. Among various types of CNC machines, the CNC vertical turning lathe machine stands out as a highly specialized and versatile tool for various manufacturing tasks.

Features of CNC Vertical Turning Lathe Machines

1. Độ chính xác cao: CNC vertical turning lathes are designed to achieve high precision cuts, ensuring accurate results in every operation.

2. Versatility: These machines are capable of performing various operations such as turning, xay xát, and drilling, making them suitable for diverse manufacturing applications.

3. Tự động hóa: With CNC technology, these machines can operate automatically, reducing human intervention and minimizing errors.

4. Easy Programming: Modern CNC vertical turning lathes come with user-friendly interfaces that allow for easy programming and setup.

Applications of CNC Vertical Turning Lathe Machines.The CNC vertical turning lathe machine is widely used in various industries such as automotive, Không gian vũ trụ, and medical. Một số ứng dụng phổ biến bao gồm:

1. Manufacturing of automotive parts and components.

2. Fabrication of machine components and machinery parts.

3. Production of precision-made metal parts for aerospace applications.

4. Manufacturing of medical equipment components.

Advantages of Using CNC Vertical Turning Lathe Machines

1. Improved Product Quality: The high precision capabilities of these machines ensure consistent quality in every product produced.

2. Increased Efficiency: Automation and easy programming result in increased efficiency and faster turnaround times.

3. Cost Reduction: The precision and efficiency offered by CNC vertical turning lathes reduce the need for rework and waste, leading to cost reduction.

4. Scalability: These machines can be easily scaled to handle different production volumes, making them suitable for both small and large-scale manufacturing operations.

Kết luận, the CNC vertical turning lathe machine is an essential tool in modern manufacturing. Its versatility, độ chính xác, and efficiency make it suitable for various industries and applications. Understanding its capabilities and limitations is crucial for effective use in manufacturing operations.